Troika AniCAM Micoscope Print Inspection

AniCAM HD™ Plus menghasilkan pengukuran yang tepat dan dapat diulang untuk gulungan Anilox, silinder Gravure, dan Flexoplates. Dengan teknologi PIXELOC™ yang canggih dan kompensasi getaran, ini memastikan akurasi dan mengurangi pemborosan selama penyiapan mesin cetak. Mudah digunakan dengan lensa yang dapat diganti dengan cepat.

AniCAM HD™ Plus

AniCAM HD™ Plus merupakan kemajuan terbaru dalam perangkat pemeriksaan pra-cetak, yang menawarkan pengurangan yang telah terbukti dalam waktu Make-Ready-Waste dan Job Setup. Dengan memberikan pengukuran yang tepat untuk Anilox Rolls, Gravure Cylinders, dan Flexoplates, alat ini memastikan penyiapan yang benar pada percobaan pertama lebih dari 90%.

Didesain secara khusus untuk menjadi alat yang praktis dan efektif bagi setiap printer, AniCAM HD™ Plus yang baru, memastikan pengukuran yang konsisten dan akurat dalam lingkungan produksi apa pun. Kompensasi getaran yang disempurnakan, dipadukan dengan teknologi PIXELOC™, meniadakan kebutuhan akan tabel getaran, memastikan pengukuran yang akurat dan dapat diulang.

Perangkat lunak yang menyertainya mudah digunakan, intuitif, dan menawarkan fokus, pengaturan, serta konfigurasi otomatis, menjamin konsistensi antara operator dan lokasi kerja.

AniCAM HD™ Plus Features

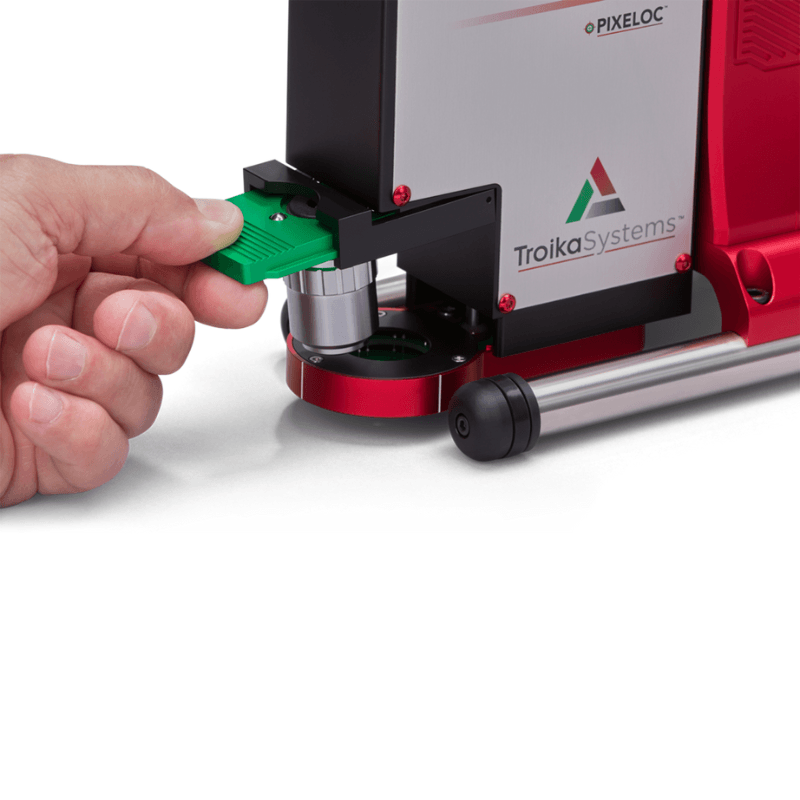

- Quick Change Lens System

Effortless lens adjustments with magnetic locks and auto-detect software, ensuring consistent and precise measurements. - Vibration Compensation

No need for antivibration tables—our system delivers accurate measurements even in challenging environments or directly on press. - PIXELOC™ Technology

Experience Troika’s exclusive PIXELOC™ motor system, ensuring accurate focus and control for superior precision. - Intuitive Software

User-friendly software guarantees fast setup and reliable results, making it easy for operators of all skill levels to achieve consistent measurements. - Auto-Focusing

Automatically define cell boundaries, ensuring measurement consistency across different operators and reducing manual intervention. - Comprehensive Support

Benefit from an industry leading 3-year warranty, software updates, technical support, and dedicated training, ensuring minimal disruption.

Explore Software Options

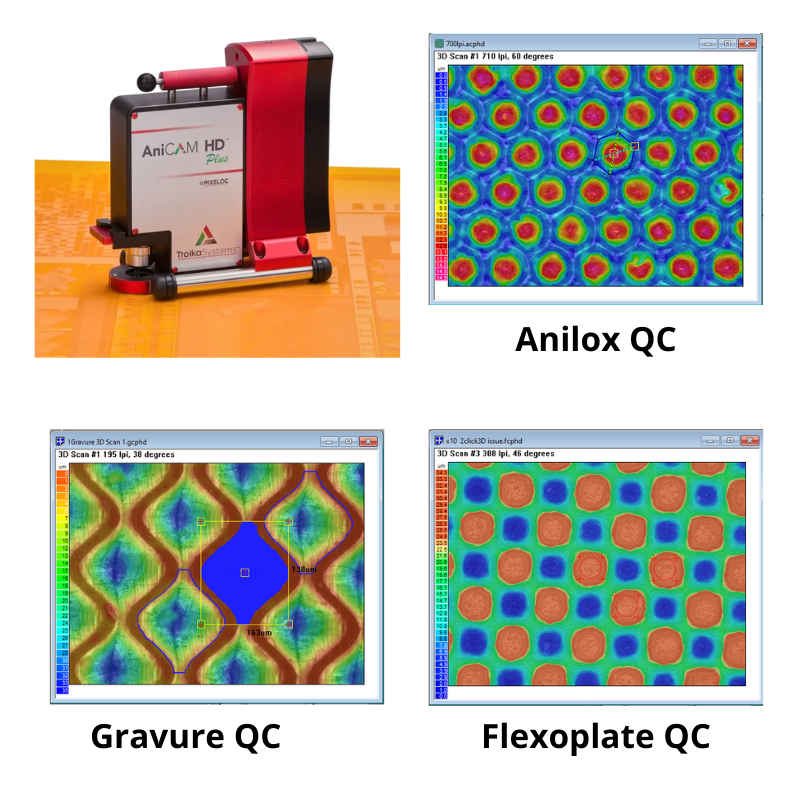

Anilox QC

The Anilox QC software delivers precise inspection of anilox rolls, ensuring consistent ink transfer and optimised quality control. Integrated with the AMS Database it enables multi-site inventory management, reducing waste and ensuring consistency.

Gravure QC

Gravure QC enables precise inspection of gravure cylinders for optimal quality control. Integrated with the CMS Database, it tracks cylinder condition, reducing inconsistencies and improving print quality through effective monitoring and maintenance planning.

Flexoplate QC

Flexoplate QC provides precise inspection and measurement of flexographic plates, ensuring optimal quality control. It helps improve ink transfer, minimise waste, and enhance print consistency by accurately monitoring plate condition and performance.

For Inquire :

info@link-match.com

Our Partners

Address

- KAWASAN BIZPARK PULOGADUNG Jl. Raya Bekasi KM.21,5 Blok B1/05 Cakung - Jakarta Timur 13920

- 021 3886 5262 & 021 3886 5267

- 0811 9840 350